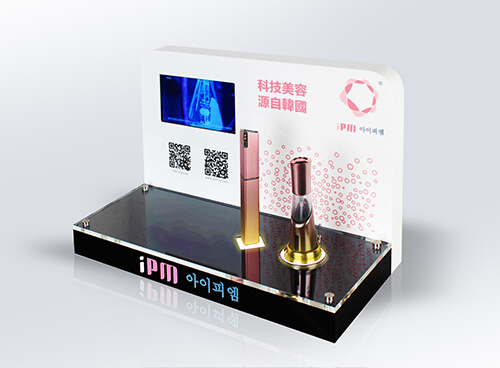

Worth To Have A Look! Acrylic Hard-coating Technology!

Acrylic is a relatively fashionable material in recent years. This material was already available a few years ago. However, due to the increase in demand of materials which with characteristics of light weighted and high hardness, acrylic stands out among many materials.

Acrylic, also called plexiglass, is a macromolecular polyester compound. Due to its low hardness, scratches are easy to occur, so the surface must be hardened. This process is called acrylic hard coating, and some people call it coating finish. The following is a detailed introduction to the hard coating of acrylic.

Three methods of surface modification technology:

01. Surface coating hardness modification

The surface coating hardness modification is well-known as hard coating treatment. It is to apply a layer of high-hardness material on the surface of the board to increase the hardness. The materials that can be coated are usually inorganic substances, silicone coatings, fluorocarbon paints, etc. The surface coating is divided into physical coating and chemical coating according to the nature of the combination. The combination of the physical coating and the board only uses the van der Waals force between the film and the board; However, the molecules in the chemical coating can cross-link with the functional groups in the side chain of the plate, resulting in a stronger chemical bond, so the adhesion of the chemical coating is better and more reliable.

02. Coating finish

Coating finish(generally completed by PVD method) is plating metal, metal oxide, or other inorganic substances on the surface of the board by PVD method.

PVD refers to the use of low-voltage, high-current arc discharge technology under vacuum conditions, using gas discharge to evaporate the target and ionize both the vaporized material and the gas, and the acceleration of the electric field to make the vaporized material and its reaction product deposit on the workpiece. The film applied after PVD has the advantages of high hardness, low friction coefficient, good wear resistance, and chemical stability.

03. Surface chemical treatment

Surface chemical treatment mainly uses laser and other methods to change the surface structure of the board.

The surface hardness value of acrylic is expressed by H value, which generally refers to its surface scratch resistance. The surface of ordinary acrylic board can only reach about HB~2H, and the acrylic board after surface hardening can be raised to 6H-8H. The higher the H value is, the better the surface hardness value of the object.

However, due to the relatively high cost of hard-coating technology, and the current hardness requirements of acrylic can meet the needs of a variety of customers, so in addition to customers who have high requirements for hardness, the acrylic hard coating is rarely performed during production.

Although there are many ways to change the surface hardness of plastic sheets, the original optical properties of plastic sheets can be retained, the surface coating process is currently the preferred surface hardening process for PMMA/PC sheets.

The above is the introduction of acrylic hard-coating,if you want to know more, please follow us.