6 Tips For Hitting A Tight Deadline On Your Next Point Of Purchase Display Program

We are seeing an increasing trend toward shorter and shorter deadlines for point-of-purchase display and in-store marketing programs. Increased competition among retailers, mounting industry financial pressures, and a rapid acceleration in product innovation have combined to reduce planning horizons and production lead times for retail store display programs.

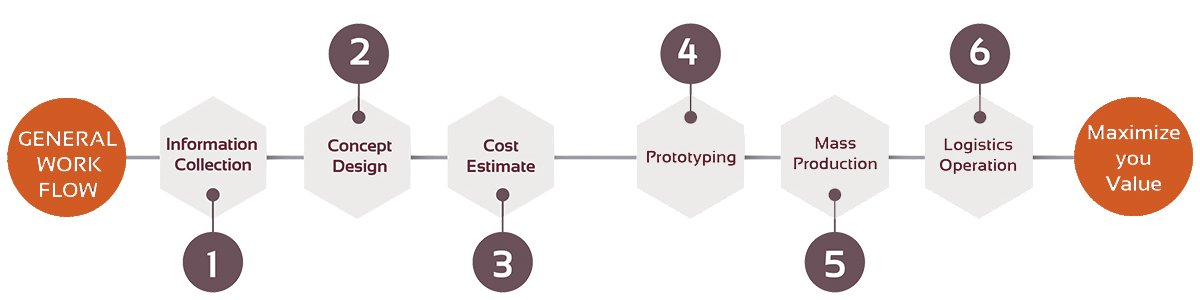

So what is the best way to reduce lead times without breaking the bank? Here are 6 tips:

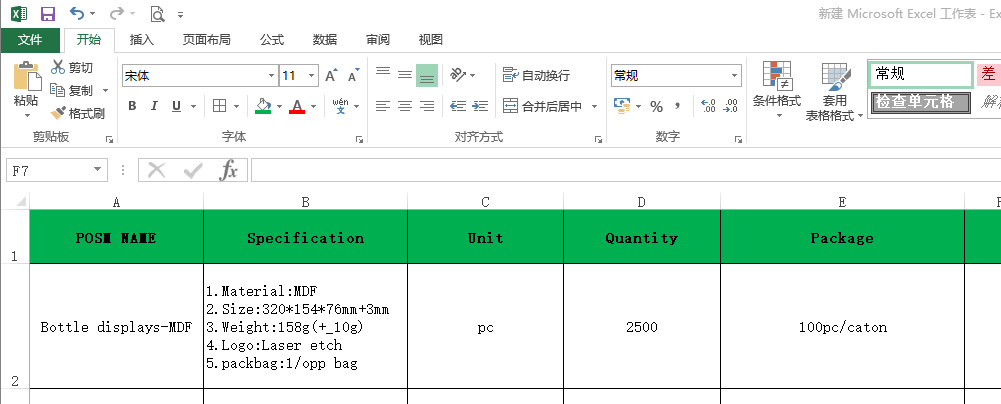

1) Define Your Point of Purchase Display Requirements Clearly

- A lot of time is often wasted as a result of poorly defined requirements or loose display specifications. It is best to have your product and display specifications gathered in advance, including

- Product dimensions and weights

- Number of SKUs

- Basic plan-o-gram for how you would like the products displayed, including the number of facings and total quantity of each SKU per shelf, hook, etc.

- Basic material requirements including material types, finish requirements, etc.

- Display dimensions

- Packing and shipping requirements, including anticipated transportation method.

2) Prepare Art Work in Advance

Have your logo and any other camera-ready art work prepared in advance and submitted as vectored artwork in a PDF, EPS, AI, or other acceptable formats. The goal is to minimize the back-and-forth between your graphics team and your supplier’s printing team. Reducing pre-press time can make a big difference in making crucial deadlines.

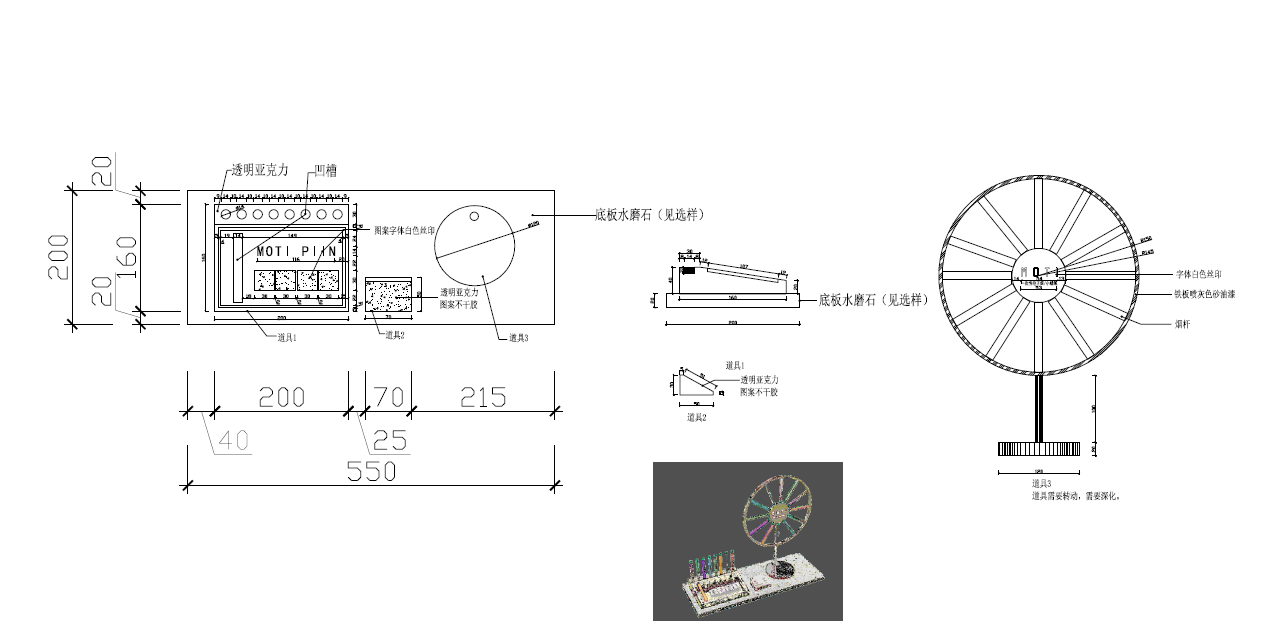

3) Cut Prototyping Time

Prototyping time can be reduced by ensuring that your point of purchase display utilizes common materials that are readily available in the market. Steer clear of highly specialized materials that may be hard to get quickly. Prototyping time can also be reduced by ensuring the manufacturer has a clear and complete set of manufacturing drawings so there is no guesswork involved.

If the prototype is being made overseas, you can expedite it by sending it airfreight or better yet, you may be able to approve the sample using detailed pictures and videos. Ask your supplier for close-up pictures of all of the parts of the display. They also should be able to send you pictures of the sample holding weighted objects so you can determine if the display will be strong enough to hold your product. Don’t hesitate to ask for videos. Videos can show if the display tips easily, if it spins smoothly, as well as providing other valuable visual information. If you can approve your prototype with the help of pictures and videos, you can generally save several days of project time.

4) Accelerate Material Procurement

Depending on the project, it may take 1-2 weeks or more for the manufacturer to order and receive the materials required to produce your display. Staying away from highly specialized materials such as unusual laminates or powder coating finishes is always wise if your project has a tight timeline.

Another important time-saver is ensuring your manufacturer orders the materials as soon as possible in the process. Getting a PO to your supplier even before you have seen a finished prototype can help speed up the process. You can protect yourself by making the PO subject to approval of a sample or first article or production. In an ideal world, the manufacturer can order the materials as they are starting the sample so that the sample can be fine-tuned while the materials and tooling are being prepared. This approach comes with some risk, but it can also save as much as a couple weeks of valuable time.

5) Design to Your Supplier’s Capabilities

During the design process, your manufacturer will likely build the design around its capabilities. You should encourage that, particularly if you are faced with a rush project. Most manufacturers design point of sale displays in a way that minimizes outsourcing and plays to their strengths such as the type of production equipment they have.

If the manufacturer has domestic and overseas capabilities, it might make sense to produce the first batch of units domestically to meet the initial rollout dates and then make the rest overseas to help reduce the average display cost.

6) Develop a Smart Shipping Plan

Developing a smart shipping plan is really important to meeting tight deadlines. If you are launching a national program, make it a point to prioritize the shipping locations to meet the needs of the retailer. If you are shipping from the west coast, for example, you may decide that shipping to East Coast stores makes the most sense since west coast stores will have shorter shipping lanes. Similarly, it is important to know in advance how the units will need to be packed and how they will be shipped. Displays that will ship via UPS or FEDEX have drastically different packing requirements than displays that will ship to DCs on a pallet.

Identifying the right trucking companies is also important. Some trucking companies employ team drivers and can get shipments across the country in 3 days. Others might require multiple cross-docks and not be well suited to deliver to your locations. It is important to do good research to ensure you select the best option.

For more helpful tips on designing and manufacturing effective point-of-purchase displays, please contact us.