10 Common POP Display Quality Problems

Everyone wants high-quality point-of-purchase displays, but not everyone knows what to look for to ensure a quality product. Knowing the most common quality problems can give you a head start in finding and addressing quality problems that might otherwise compromise the effectiveness of your retail display. The most common quality problems to be on the lookout for are the following:

1) Weak or Broken Welds– On any metal display, it is important to check the strength of the welds and ensure that the welds are strong enough to hold the weight of your product but also endure mistreatment in the shipping process.

2) Chipping MDF– When MDF parts are cut with a dull blade, they often result in jagged edges and minor chipping. This can detract from the look of the overall display so it is important to pay close attention particularly to the edges of MDF pieces.

3) Bearings that Bind– If you have a spinning display, it is important to ensure that the bearing is a high-quality bearing. Cheap, low-quality bearings are not uncommon so it is important to test the functionality of the bearing to ensure it spins freely in both directions with the display fully loaded with product. The heavier your product the more likely the bearing is to bind over time.

4) Poor Powder Coating Finish– The finish of any retail display is a critical element of the overall quality of the display and a highly visible reflection of the quality of the product being displayed. Whether your display has a matte or a glossy powder-coated finish, check to make sure the powder coating is evenly distributed and ensure there are no scratches or blemishes in the finish. Poor powder coating can result in the finish chipping or flaking off. If metal parts are packed together, make sure they are protected by plastic or other packing materials so the powder coating does not rub off in transit. Finally, make sure your manufacturer chemically treats the metal parts before powder coating which will help protect the parts from rusting over time.

5) Inferior Sign Material and Printing– Some foam PVC products are very soft and will dent easily. Test this by sticking your fingernail into the sign and see if it leaves a dent. Signs can also have bubbles that detract from the quality of the sign. Inspect signs carefully to ensure they are bubble-free. Checking the quality of the printing is also important. Make sure the color matches your specifications and look for areas of pixilation which can compromise the effectiveness of your sign.

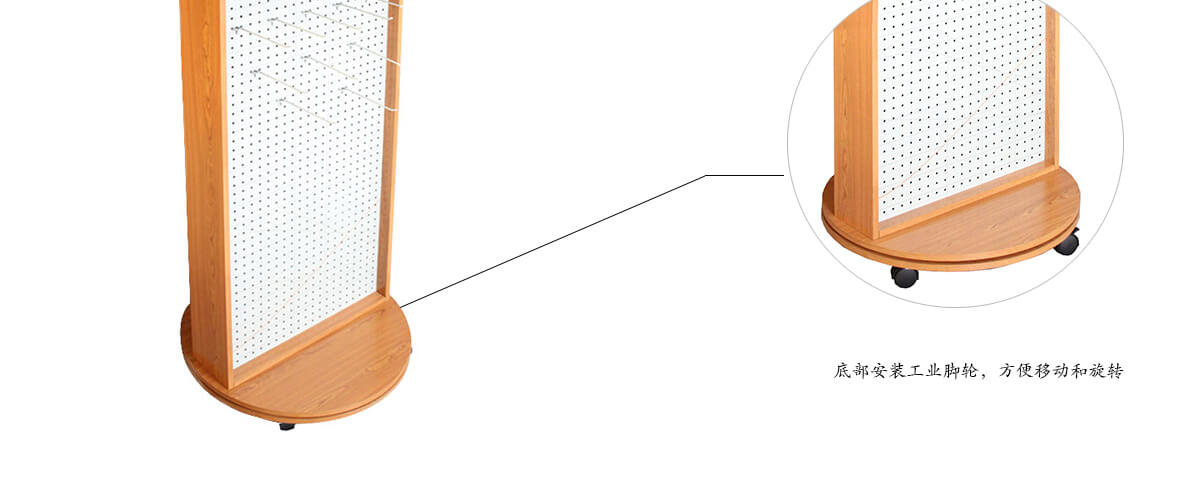

6) Sub-standard Castors- When castors fail, your display can be rendered useless. Make sure the castors on your POP display are appropriately rated for the weight of the display when fully loaded. In addition to ensuring high-quality castors, it is important to ensure the welds are strong at the points of connection. The strongest castors can fail if the castor attachment point is weak.

7) Low-Quality Acrylic- Low-quality acrylic generally turns yellow under UV lighting in retail stores. High-quality acrylic can last for 10 years without yellowing. Low-quality acrylic can also crack more easily. All acrylic, no matter what the quality, needs to be packed with adequate protection to minimize damage in shipping.

8) Cheap Hardware- Even the nicest store displays can look cheap if the hardware is cheap. Cheap hardware is often soft, easily bent, does not match the décor of the display, and may have a finish that easily chips.

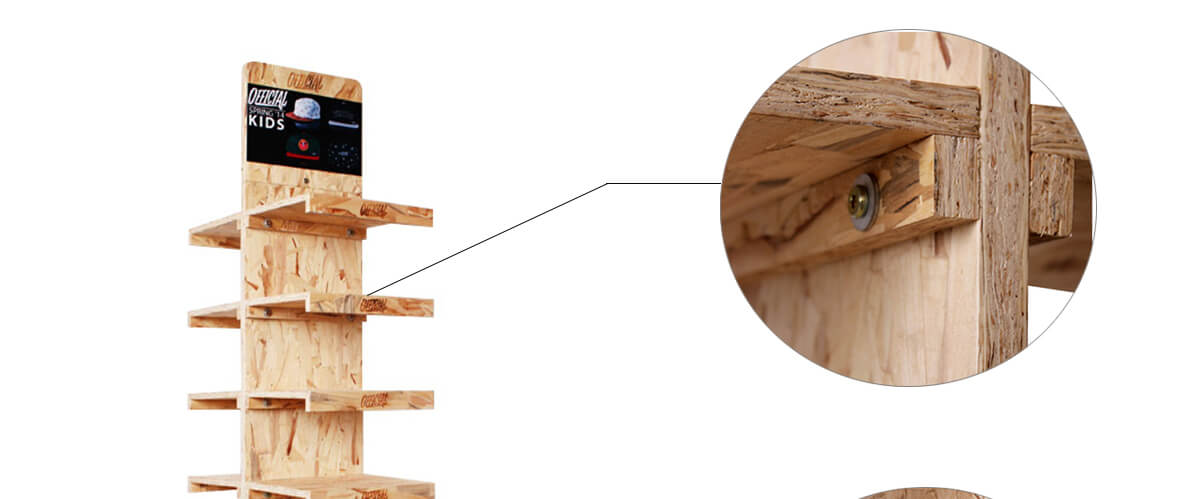

9) Misaligned Parts- Knock-down displays typically require relatively tight tolerances to ensure that holes and parts are well aligned for easy assembly. It is not uncommon to see parts that don’t properly align and are difficult to assemble. Some manufacturers make the parts of displays independent of one another and don’t take the time to assemble the units to ensure a proper fit.

10) Thin or Dented Sheet Metal- Displays with high-quality sheet metal and excellent workmanship are generally smooth and nicely finished. When the sheet metal is too thin, it is often easy to see unattractive weld marks from the underside of the sheet metal. Poorly constructed sheet metal parts often have denting which detracts from the appearance of the display.